Do I Need a Contractor Prequalification System? | FIRST, VERIFY

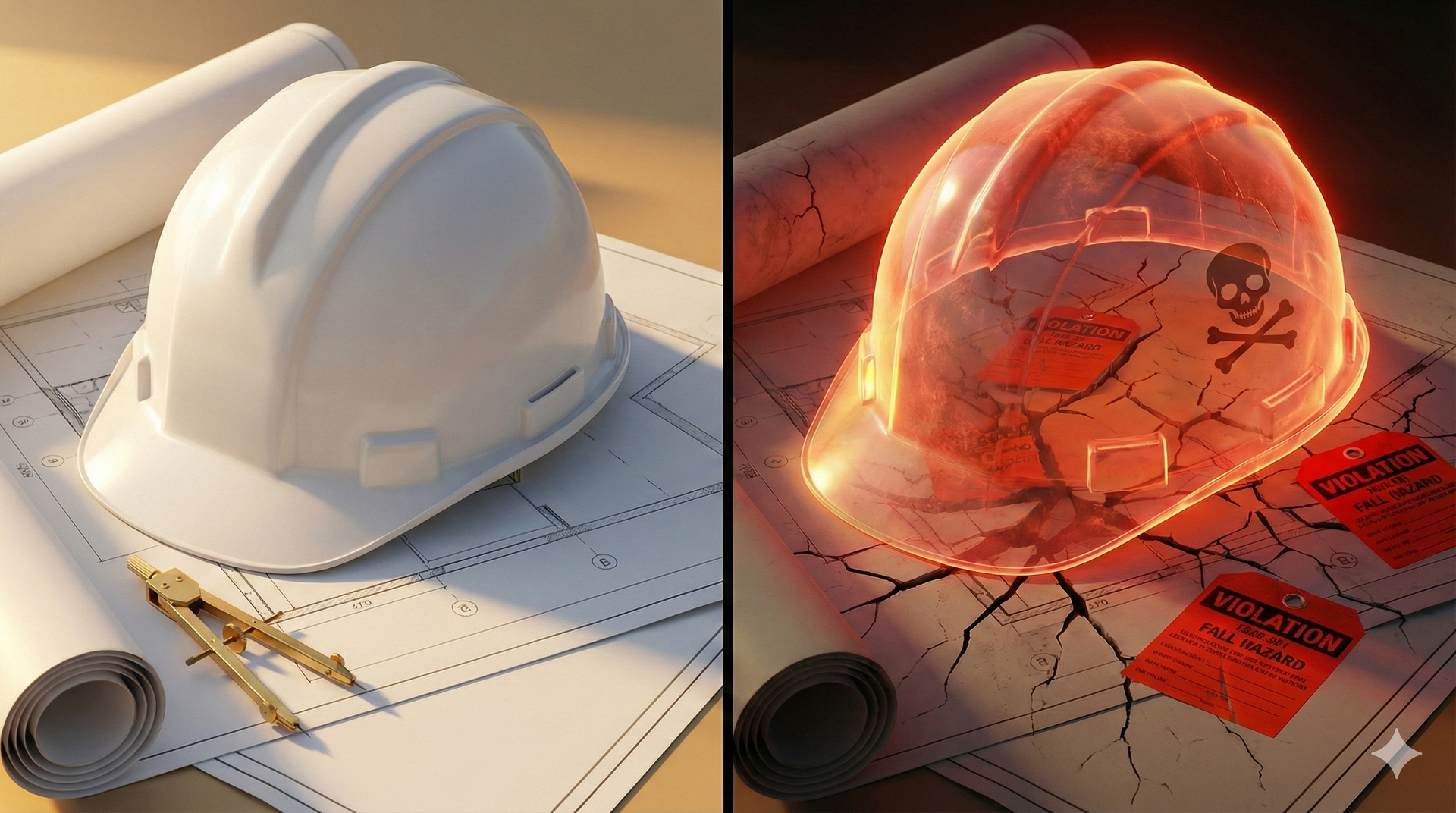

Unfortunately, many organizations overlook the need for contractor prequalification systems until it’s too late. When sourcing third-party vendors, procurement and safety managers need to consider more than price and availability they must also consider vetting through a formal prequalification process. Factors such as relying on just a single contractor, as well as the financial stability, insurance coverage, OSHA safety records and documented safety practices of third-party service providers should also be considered.

Contractor prequalification systems provide purchasing managers with the information they need to manage third-party risk, and therefore make informed procurement decisions. The most common contractor prequalification data that is collected for verification is:

- Business Attributes

- Financial

- Insurance

- References

- Bidding interests

- Safety statistics

- Safety programs and procedures

- OSHA reporting forms, NCCI Worksheets, safety policies, citations, contractor agreements, certificates, licenses, etc.

“According to the International Labor Organization (ILO), more than 2 million people die around the world due to work-related accidents or diseases, every year,” The European Pact for Sustainable Industry, points out. “This hampers not only the economic viability of companies concerned, but it climbs up, impacting along the chain up to the core clients, their ethics and reputation.”

When no contractor prequalification systems exist:

Organizations that operate without a contractor prequalification system but continue to outsource, put their companies at risk. The inherent risks of entrusting certain functions with contractors or working with suppliers for business-critical materials become more apparent when looking at recent news.

Headlines regularly detail the failure of un-vetted contractors to comply with government regulations, safety guidelines, branding standards, and corporate social responsibility practices.

These violations not only threaten employees’ physical safety. For the companies that hired the contractors or suppliers, the events can also cause massive fines, operational disruptions, and reputational damage.

For this reason alone, every organization that manages contractors would benefit from implementing a contractor prequalification system.

It is often difficult to know where to start when creating a prequalification program. Download this

Prequalification

Checklist to determine the type of information you may want to collect and review prior to committing to a contractor prequalification program.