When Things Go Right - Insurance restoration company

The fire spread so quickly that the men stopped their suppression efforts and called 911. It started when an employee for this medium-sized sawmill was welding on equipment inside the mill’s main processing building. He had followed normal procedures, including wetting down the area, but piles of sawdust and debris from the log debarking process— soaked with oil and grease leaked from equipment overhead—had caught fire nonetheless. Fires in mills happen all the time, but in this situation employees inadvertently dispersed the burning debris—sending the fire up a cable chase, rapidly spreading it throughout the building.

The first fire engine arrived within six minutes of the 911 call. By then, the fire was so intense, with smoke billowing into the sky, that the firefighters called for air support and focused on keeping the flames from spreading to nearby log decks and stacks of finished lumber. Two air tankers bombed the main processing building with retardant, and a helicopter scooped water out of an adjacent lagoon to make water drops.The building was a total loss, a charred ruin of twisted metal that had collapsed into itself. Fortunately, the rest of the facility was spared.

The site required extensive demolition and cleanup, but large wood processing machinery also needed to be removed. Much of it was salvageable, so removal had to be accomplished without further damage in an environment where heavy debris had collapsed on and around it.

After weeks of negotiations with the insurer, the restoration contractor was finally able to start work. First, environmental hazards had to be assessed and mitigated before the demo work could start. Asbestos was found in one small room, which was quarantined and quickly cleaned by an abatement team. The nearby lagoon had to be protected from runoff generated when years of accumulated industrial sludge were powerwashed off the floors.

The greatest safety concerns were electrical hazards, fall hazards and line of fire hazards.While some elevated work could be performed from aerial lifts, much of the work required climbing on debris and equipment, and on upper-level decking.

Planning for Safe Work

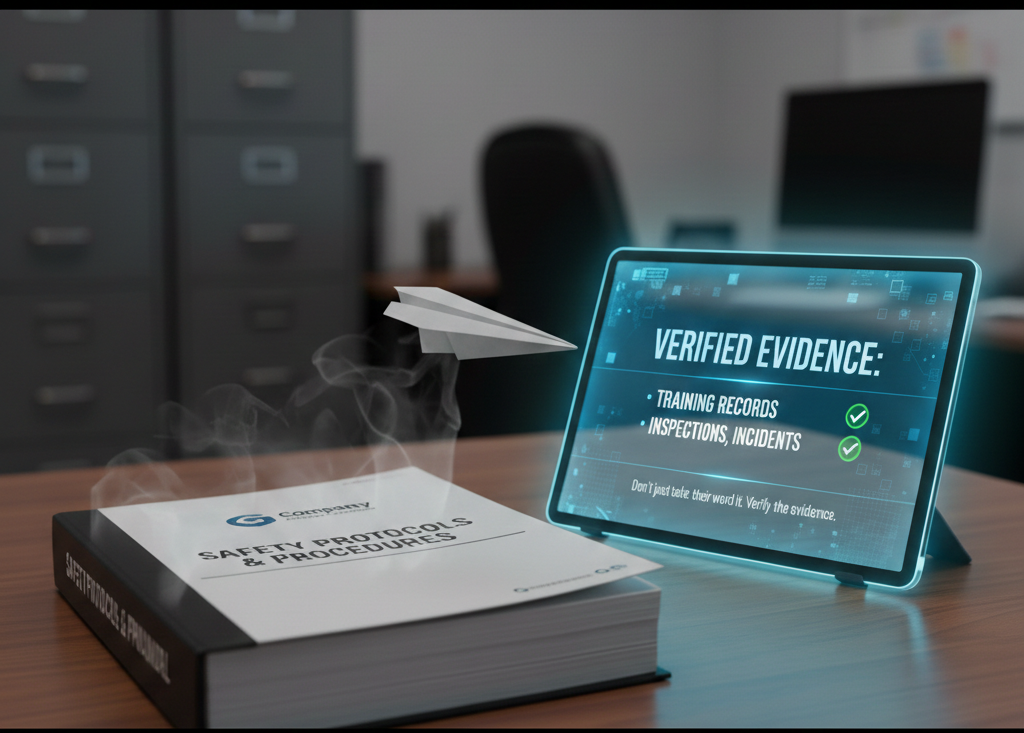

First, the safety manager required written verification from the sawmill’s management that all equipment and building electrical had been de-energized. Lockout/tagout procedures were documented and reviewed with employees prior to beginning demolition. Hard hats, safety glasses, and gloves were a 100 percent personal protective equipment (PPE) requirement; and dust mask and hearing protection were recommended. Only trained employees were allowed to operate aerial equipment or work at elevations above six feet; and fall protection was 100 percent required at elevations above six feet. Also, all work above six feet had to be pre-planned and approved by company supervisors. Daily pre-work meetings were held, where all hazards were identified and recommended safe work procedures were reviewed with affected employees. Site-specific job orientation was required for all new employees, who were required to sign written documentation. Hot work permits were filled out and approved by company safety personnel prior to performing any spark-producing activity.

Most of the fall protection issues were caused by leading edge conditions and holes created after machinery had been craned out. In many of the cases, the equipment was large (25 ft. x 15 ft., for example), projecting up through the second level of the building. Removing this equipment left holes in upper-level platforms; and no work could be performed within six feet of an edge or hole without a barrier or fall protection (and a good plan). When a company creates a hazard, it has a special responsibility to protect workers, as well as extra liability in the event of an injury.

Obviously, fall protection PPE was in place while removing machinery that penetrated any elevated surfaces. There were plenty of large H-beams to tie off from, so the company used wire rope retractable fall protection. Afterwards, barriers were installed around every opening with railing sections fabricated by welding a 11/2-inch in diameter pipe onto flat steel plates six feet on center; and threaded with 3/8-inch wire rope at 21 and 42 inches. Caution flags were hung every two feet.

Line of fire hazards existed wherever gravity or the sudden release of tension could cause injury or death. Piles of interwoven steel had to be removed, and any time one piece is moved it can generate energy by falling or causing other pieces to fall. Total situational awareness is mandatory. Obviously, powered equipment was used wherever possible, but in the effort to minimize damage to salvageable machinery, hand work was necessary to cut the equipment free.

On more than one occasion, the safety manager stopped work to require a written job hazard analysis before continuing. The priority given to safety on this project meant that every task was assessed and planned before action was taken, changing the protocol from thoughtless routine to thoughtful caution. Every day was the first day, an acknowledgement that hazards evolve; that unknowns exist.

This could only have happened in a restoration company with a strong commitment to safety rules and procedures. Management had an absolute commitment to a safe workplace. The crew was engaged during safety training, toolbox talks and daily hazard identification; and they were proactive whenever they saw unsafe activity.

There were only two near-misses and a cut requiring a Band-Aid…a complicated, high-risk demo job with zero OSHA recordable incidents. That didn’t happen by accident.