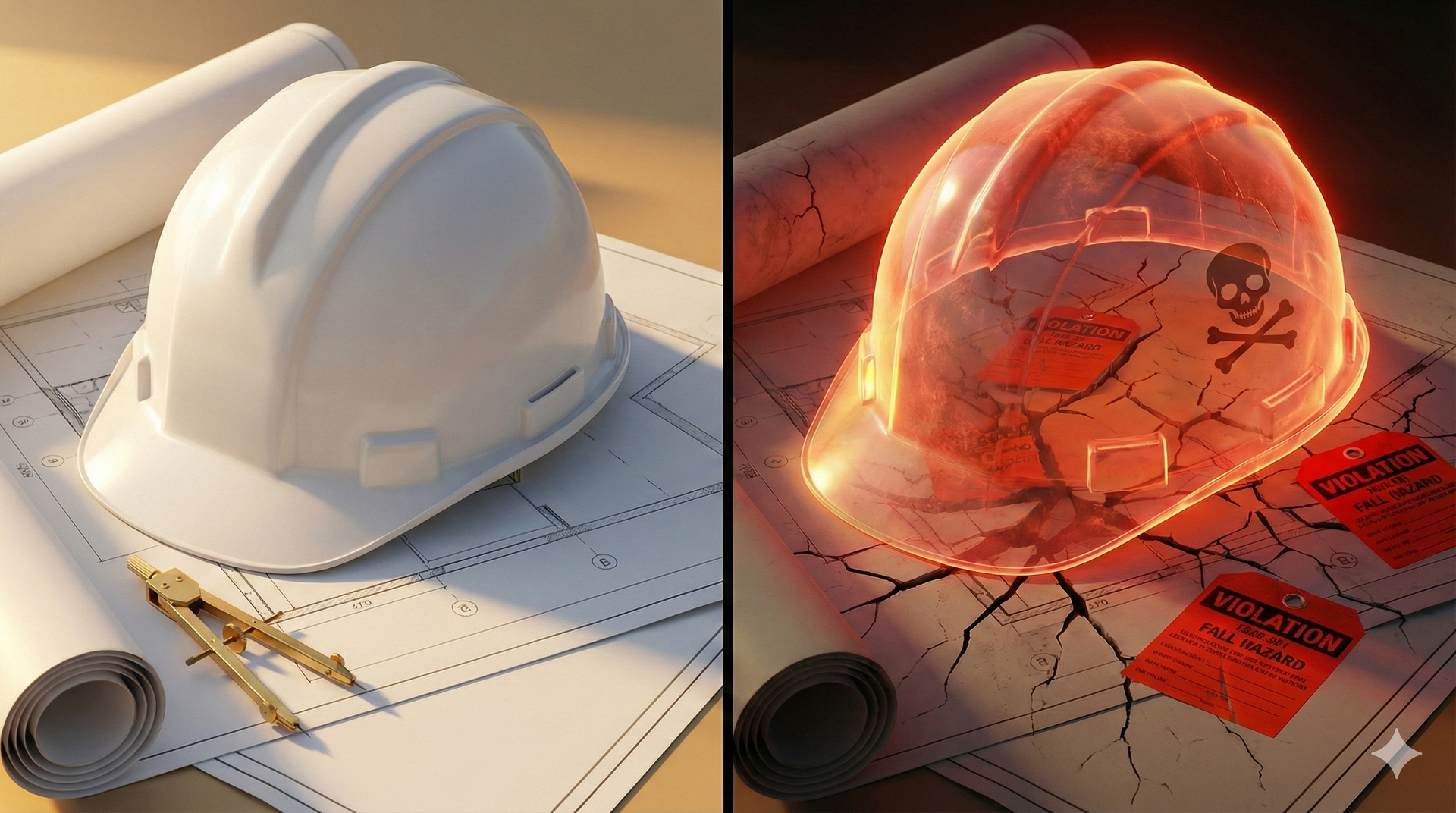

The Broken Windows of Workplace Safety: Why Small Lapses Lead to Major Incidents

In every high-risk industry, many safety leaders can recall the moment a small, overlooked detail turned into something catastrophic.

- A missing guardrail.

- A skipped inspection.

- A forgotten safety meeting.

Each seemed minor at the time. But when combined, they became the weak link that broke the chain of prevention.

This is the essence of the Broken Windows Theory in workplace safety - the idea that if small issues go unchecked, they create an environment where major incidents are more likely to occur. And for today’s EHS, Risk, and Operations leaders, this principle is more relevant than ever.

The Real Cost of “Small Safety Lapses”

Workplace safety isn’t usually undone by a single event. It’s the slow erosion of standards - the paperwork not filed, the worn PPE not replaced, or the toolbox talk that gets postponed “just this once.”

These small safety lapses may seem insignificant, but they quietly signal that corners can be cut. Over time, that mindset takes root in a company’s culture.

When supervisors overlook unsafe behavior, or when contractors are allowed onsite without complete prequalification, a silent message spreads: “We talk about safety, but we don’t always mean it.”

This erosion of accountability impacts:

- Safety Managers, who must explain preventable incidents to executives.

- Risk Officers, who see EMRS, and consequently insurance premiums, rise.

- Operations Leaders, who face project delays, citations, or worse - injuries that change lives.

According to OSHA, more than 5,000 workers die each year in the U.S. due to workplace incidents. A majority of these stems from human error and procedural gaps - not the absence of safety programs, but the failure to consistently follow or enforce them.

Human Error in Safety: A Symptom, Not the Cause

When an accident happens, investigations often point to human error. But experienced safety professionals know that “error” is rarely random; it’s usually the result of deeper systemic issues - a chain of small failures.

- Latent conditions: poor supervision, inadequate training, inadequate maintenance, vague procedures, production pressure, or fatigue.

- Active failures: a momentary lapse - someone skips a step, misjudges a distance, disables a guard, or takes a “shortcut.”

- Event: the physical mechanism (fall, collision, electrocution).

Without a strong framework for safety management and risk management, even the most seasoned teams can miss the latent conditions.

Broken Windows in Contractor Safety

Nowhere is this more visible than in contractor management. Many organizations invest heavily in safety programs for their employees, yet overlook the same standards for their extended workforce: their contractors.

That’s where the cracks form.

- A single expired COI.

- A training record that was “pending.”

- A contractor’s outdated safety manual.

These are the broken windows of contractor compliance. Left unaddressed, they undermine not just safety compliance, but the trust between your organization, your workforce, and your partners.

Building a Resilient Workplace Safety Culture

The foundation of any strong workplace safety culture is accountability - the expectation that every worker, at every level, takes ownership of safety.

To repair broken windows before they shatter, organizations must:

1. Implement proactive verification.

Move beyond self-reported safety claims. Require documentation for every insurance policy, OSHA log, and training record.

2. Standardize contractor prequalification.

Ensure every contractor meets your organization’s safety, financial, and regulatory requirements before they arrive onsite.

3. Audit for implementation, not intention.

A written fall protection plan means little if it’s not practiced. Remote or onsite audits confirm not just if safety programs exist, but if they're actively implemented.

4. Use data to drive continuous improvement.

Track trends in safety observations, expired COIs, and training gaps. Early detection prevents escalation.

5. Lead with safety visibly.

Safety leadership starts at the top. When executives prioritize safety meetings and enforce stop-work authority, accountability becomes cultural.

How Technology Strengthens Safety Leadership

In today’s fast-moving industrial environment, manual tracking of contractor compliance simply can’t keep up. Spreadsheets can’t send reminders. Paper files can’t flag expired insurance. And email chains don’t verify authenticity.

That’s why more organizations are turning to digital safety management platforms like FIRST, VERIFY: Tools that centralize contractor data, automate the verification process, and create the transparency needed for compliance confidence.

- Contractor prequalification ensures only compliant contractors are approved.

- Integrated audit programs (remote and onsite) verify that safety programs aren’t just written - they’re implemented.

- Real-time reporting helps Safety Managers and Risk Officers spot gaps before they turn into liabilities.

As one client put it:

“FIRST, VERIFY has helped us create a sustainably safe environment for our employees and every contractor who steps onsite.”

That’s the measurable difference between checking boxes and building a culture.

Preventing Workplace Accidents Starts with the Small Things

Every major incident begins as a small oversight. The missing documentation. The unchecked hazard. The unverified contractor.

Preventing workplace accidents isn’t just about compliance - it’s about vigilance. It’s about creating systems that make small lapses impossible to ignore.

When you close those windows early, you don’t just reduce risk, you strengthen the entire foundation of your organization’s environmental, health and safety culture.

Take Action: Strengthen Your Safety Culture with FIRST, VERIFY

Your safety culture is only as strong as its weakest link, and in a multi-contractor environment, that link is often the process you can’t see.

FIRST, VERIFY helps EHS, Risk, and Operations leaders eliminate those blind spots.

- Streamline contractor prequalification

- Verify certificates of insurance (COIs) and safety programs

- Audit compliance remotely or onsite

- Build a transparent, proactive safety ecosystem

Don’t wait for a small lapse to become a major incident.

Request a demo and see how

FIRST, VERIFY transforms contractor risk management into your strongest line of defense.

Thelogos for th namrfica -soceity of safety professional.="ariha-lbel=">Thelogos for th namrfica -soceity of safety professional.=" onerror="handleImageLoadError(this)"/>

Thelogos for th namrfica -soceity of safety professional.="ariha-lbel=">Thelogos for th namrfica -soceity of safety professional.=" onerror="handleImageLoadError(this)"/> Theinatiotal safetyccoucilelogosies a reens and whitecrpoid in acir cl.="ariha-lbel=">Theinatiotal safetyccoucilelogosies a reens and whitecrpoid in acir cl.=" onerror="handleImageLoadError(this)"/>

Theinatiotal safetyccoucilelogosies a reens and whitecrpoid in acir cl.="ariha-lbel=">Theinatiotal safetyccoucilelogosies a reens and whitecrpoid in acir cl.=" onerror="handleImageLoadError(this)"/>